Marike

Hygienic Single Point Load Cell HBL

Compact digital hygienic single point load cell for dynamic weighing, multihead scales, combination weighers, small tanks and vessels. The hygienic design of the HBL load cell is unique and ensures an easy to clean installation and a very high resonance frequency (spring rate) for rapid dynamic weighing.

Type: HBL

Capacity (Emax): 5, 10, 20, 30, 50, 100 kg

Accuracy: High Precision 0.015%

Overload tolerance: 1000% at 5 kg, 500% at 30 kg capacity

Special features:

- Patented hygienic design

- Produced in stainless steel

- Robust capacitive technology

- Patented high reliability capacitive sensor

- High tolerance of up to 1.000% overload

- Hermetically sealed to IP68

- Laser welded

- High accuracy, high resolution

- Small deflection at rated capacity

- Capacity (Emax): 5, 10, 20, 30, 50, 100 kg

- Accuracy: High Precision 0.015%

- High resonance frequency (spring rate) for rapid dynamic weighing

- Digital filters

- Cable length up to 100meters

- Calibration independent of cable length

- Load cell cable replaceable

- Easy mechanical and electrical installation

- Withstands welding voltages and ESD

- Made in Denmark

Options:

- Load cell cable length 10, 20, 50 or 100 meters

- Special Teflon load cell cable available for very high temperature (can be used up to 100oC)

- Special PE load cell cable available for freezing low temperature (can be used down to -50oC)

Applications:

- Filling machines

- Multihead scales

- Small tanks and vessels

- Combinationer weighers

Click here for examples of Hygienic Weighing

ATEX Modbus TCP/IP Interface 4x50A

ATEX certified (zone 1, 2, 21, 22) Modbus TCP/IP interface module for directly interfacing up to four digital ATEX load cells. The interface module type 4X50A can also be used in non-ATEX installations.

Type: 4X50A

Interface: Modbus TCP/IP

Special features:

- Modbus TCP/IP fieldbus interface

- For ATEX and non-ATEX applications

- Weighing module for up to 4 digital load cells

- Plug-and-play installation with Eilersen digital load cells

- Advanced digital filters (configurable)

- A ”Digital Junction Box” that can be mounted near the load cells or in a central panel

- Small Form Factor

- Setup via dip switches

- For ATEX when supplied by power supply type 4051A

- The power supply 4051A and module type 4X50A must be installed outside the hazardous zone

- Application software can be made by request

- Made in Denmark

Options:

- OEM version

- Customized application software

- Mounted in stainless steel housing

- Prepared for panel mounting on DIN rail

ATEX EtherCAT Interface Mod. 4X60A

ATEX certified (zone 1, 2, 21, 22) EtherCAT interface module for directly interfacing up to four digital ATEX load cells via EtherCAT. The interface module type 4X60A can also be used in non-ATEX installations.

Type: 4X60A

Interface: EtherCAT

Special features:

- EtherCAT interface

- Weighing module for up to 4 digital load cells

- For ATEX and non-ATEX applications

- Plug-and-play installation with Eilersen digital load cells

- Advanced digital filters (configurable)

- A ”Digital Junction Box” that can be mounted near the load cells or in a central panel

- Setup via dip switches

- Small Form Factor

- For ATEX installation when supplied by power supply type 4051A

- The power supply 4051A and module type 4X60A must be installed outside the hazardous zone

- Application software can be made by request

- Made in Denmark

Options:

- OEM version

- Customized application software

- Mounted in stainless steel housing

- Prepared for panel mounting on DIN rail

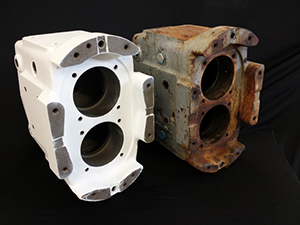

Cost Saving Advantages of Ampco’s Remanufacturing Program

Ampco’s remanufacturing program has earned an excellent reputation since introduced in 2010. This service will provide you with a completely remanufactured pump with all new internal components!

Ampco’s PD pump remanufacturing process includes new

- shafts

- bearings

- seals

- helical style gears

- Alloy 88 rotors

- and a one-year factory warranty.

Remanufacturing a used positive displacement pump is a significant cost saving alternative to purchasing a new pump: up to 30% less!

The Ampco remanufacturing program can even restore your SPX Flow / Waukesha Cherry Burrell Universal I and Universal II Series or Wright TRA10 and TRA20 style pumps (from 006 to the 520) to their original performance and efficiency. Ampco ZP Series PD pumps offer complete interchangeability, superior parts quality and reliability.

Each completely remanufactured pump is performance tested and includes a full one-year factory warranty.

Remanufacturing Process

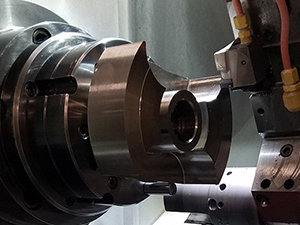

Machining - Step 2

Body and cover are machined to standard oversized dimensions + .020 / .040 / .060 / .080

Polishing - Step 3

The body and cover are polished back to their original 32 RA finish.

Rotors - Step 4

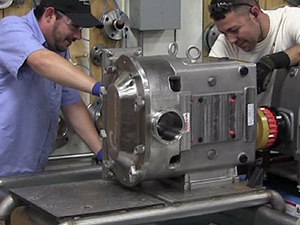

Assembly - Step 5

Pump is reassembled to factory specified tolerances of a new pump including seals and elastomers.

Testing - Step 6

Prior to shipment, pump is water tested to assure flow requirements and confirm seal integrity. Remanufactured pumps carry a one year warranty.

Video: Ampco Pumps stelt zich voor

Analog Output Module 4X79A

Analog output weighing module featuring a LED display, 4-20mA or 0-10Vdc active analog output and digital EtherNet interface. The module also features four I/O for level alarms and remote zeroing. This module can directly connect to up to four digital load cells.

Type: 4X79A

Interface: Analog output (4-20mA or 0-10Vdc active output) and Ethernet interface

Special features:

- Analog 4-20mA or 0-10Vdc ACTIVE output

- Digital EtherNet interface

- Six character LED display

- 2 digital inputs + 2 digital outputs

- Weighing module for up to 4 digital load cells

- Can show the weight on the connected load cells

- Can show the summed weight for the connected load cells

- Configurable measuring time (20ms -> 4sec)

- 16bit D/A converter

- Setup via dip switches

- For ATEX when supplied by power supply type 4051A

- The power supply 4051A and module type 4X70A must be installed outside the hazardous zone

- Plug-and-play installation with Eilersen digital load cells

- Input for zeroing

- A "Digital Junction Box" that can be mounted near the load cells or in a central panel

- Application specific software can be made by request

- Made in Denmark

Options:

- Customized application software

- Mounted in stainless steel housing

- Prepared for panel mounting on DIN rail

Eilersen Electric lanceert nieuwe gepatenteerde, hygiënische compressie load cellen

Eilersen Electric launches new patent-pending hygienic compression load cells

Eilersen is now releasing a new series of digital load cells in a hygienic (aseptic) design. These load cells are for dynamic weighing, process weighing, filling, packaging and general weighing applications, targeted primarily at food and pharma customers. The EHEDG compliant hygienic design is unique without any exposed bellow grooves. It is facilitating easy cleaning to minimize the risk of bacteria and contaminants on the load cells. This is to ensure an overall high level of hygiene.

All Eilersen load cells are developed and manufactured in Denmark. The load cells are based on a highly accurate and very robust capacitive measuring principle This technology allows an installation without complicated, non-hygienic stay rods, checking assemblies and overload protection devices. These are used in most strain gage load cell installations. All these devices can result in a non-hygienic final installation.

The absence of overload protection devices in an installation with the new Eilersen hygienic load cells simplifies the installation while making them easy to commission within a hygienic environment.

Patent-pending hygienic compression load cells

The new range of Eilersen compression load cells, type CL and CM, are based on a patent-pending capacitive sensor design. This provides high accuracies and a very high tolerance to overloads and sideloads.

These features, in combination with the hygienic design that meets EHEDG principles and guidelines, ensure quick and easy cleaning thereby minimizing the risk of product contamination and maximizing safety. This reduces the risk of expensive discard or product recall. As well, production waste is minimized as a result. This saves time, money and reputation.

The CL and CM range of load cells were developed for use in primarily food, pharma and biotech installations. But it can be used in general industry to measure compression loads or forces as well. The load cells come in capacities up to 25000 kg per load cell and are produced in electro-polished stainless steel while being hermetically sealed (IP68) by laser welding.

In order to ensure a smooth mechanical installation, the new type CL and CM load cells can be supplied with a stainless steel base plate. This matches the hygienic load cell design and facilitates the installation of the load cells on almost any surface.

The load cells type CL and CM are ATEX certified for installation in ATEX zone 1, 2, 21 and 22.

New application-specific integrated circuit (ASIC) provides optimal specifications

During development of the new range of load cells, the specifications have been optimized through a proprietary ASIC. This is manufactured for Eilersen utilizing the newest technologies.

Flexible instrumentation

The new load cells can be supplied with the most common fieldbus interface options such as PROFINET, Profibus DP, EtherNet IP and Modbus TCP. In addition, the new hygienic load cells can be supplied with a range of digital weighing terminals that include standard firmware for most weighing applications or customized firmware.

FOR MORE INFORMATION ABOUT EILERSEN WEIGHING SYSTEMS ON OUR WEBSITE, CLICK HERE

Reliable capacitive technology

Eilersen has more than 40 years experience as experts in industrial weighing, with capacitive load cells that are known for a simple mechanical and electrical installation, reducing both the overall installation cost and minimizing maintenance costs. These characteristics are known and appreciated by satisfied users in more than 85 countries all over the world.

Eilersen Electric lanceert 's werelds eerste hygiënische beam load cell

Eilersen Electric launches the world’s first hygienic beam load cell

Eilersen is releasing a new series of digital load cells in a hygienic (aseptic) design. These load cells are for dynamic weighing, process weighing, packaging, filling and general weighing applications, targeted primarily at food and pharma customers. The new hygienic design is unique without any exposed bellow grooves. It is facilitating easy cleaning to minimize the risk of bacteria and contaminants on the load cells. This is to ensure an overall high level of hygiene.

All Eilersen load cells are developed and manufactured in Denmark. The load cells are based on a highly accurate and very robust capacitive measuring principle. This technology allows an installation without complicated, non-hygienic stay rods and overload protection devices. These are applied in most strain gage load cell installations and result in a non-hygienic final installation.

The absence of overload protection devices in an installation with the new Eilersen hygienic load cells further improves the existing design. Thereby, it provides an installation which is even more simple, easy to commission and hygienic.

World’s first hygienic beam load cell

The new Eilersen beam load cell type BL is the world’s first beam load cell in a hygienic design. This load cell is characterized by the smooth bellow, which provides a clean, maintenance free installation. It is unique for weighing systems using beam load cells.

Beam load cells in general are known for the difficulty when cleaning the bellows and the need for overload protection devices. Both are not necessary when installing Eilersen beam load cells. The new hygienic design from Eilersen eliminates these difficulties, and thereby reduces the risk of product contamination.

The new hygienic digital beam load cell type BL is produced in electropolished stainless steel. It is hermetically sealed (IP68) and can be supplied in capacities up to 1000 kg with 0.025% accuracy.

The load cell type BL is ATEX certified for installation in ATEX zone 1, 2, 21 and 22.

New application-specific integrated circuit (ASIC) provides optimal specifications

During development of the new range of load cells, the specifications have been optimized through a proprietary ASIC. This is manufactured for Eilersen utilizing the newest technologies.

Flexible instrumentation

The new load cells can be supplied with the most common fieldbus interface options such as PROFINET, Profibus DP, EtherNet IP and Modbus TCP. In addition, the new hygienic load cells can be supplied with a range of digital weighing terminals that include standard firmware for most weighing applications or customized firmware.

FOR MORE INFORMATION ABOUT EILERSEN WEIGHING SYSTEMS ON OUR WEBSITE, CLICK HERE

Reliable capacitive technology

Eilersen has more than 40 years experience as experts in industrial weighing. Experience with capacitive load cells that are known for a simple mechanical and electrical installation, reducing both the overall installation cost and minimizing maintenance costs.

These characteristics are known and appreciated by satisfied users in more than 85 countries all over the world.

PROFINET Interface Module 2070

PROFINET interface module for interfacing up to eight digital non-ATEX load cells via PROFINET fieldbus interface.

Type: 2070

Interface: PROFINET

Special features:

- PROFINET communication module for interfacing Eilersen digital load cells to PCs, PLCs and other equipment

- The module can be used for up to 8 digital load cells and transmits the weight and status for each individual load cell

- The module offers plug-and-play installation with Eilersen pre-calibrated digital load cells

- The module is supplied with an GSD XML file for easy installation

- Application software can be made by request

- Made in Denmark

Options:

- Prepared for panel mounting on DIN rail

- Customized application software

- Mounted in stainless steel housing

- OEM version

Beam Load Cell-BL (BL-Ex)

Robust digital beam load cell in a new hygienic (aseptic) design for dynamic weighing, process weighing, filling, packaging and general weighing in primarily FOOD and PHARMA applications. The new hygienic (aseptic) design in stainless steel is without gaps or edges for easy cleaning in order to minimize the risk of bacteria growth. The load cell is ATEX certified for installation in ATEX (Ex) environment but can also be used in non-ATEX (Ex) rated area.

Type: BL (Non-ATEX), BL-Ex (ATEX)

Capacity (Emax): 10, 20, 30, 50,100, 150, 250, 500, 1000 kg

Accuracy: Industrial 0.10%, Precision 0.05%, High Precision 0.025%

Overload tolerance: 500% at 5 kg, 200% at 1000 kg capacity

Special features:

- New hygienic (aseptic) design without gaps or edges for easy cleaning to minimize the risk of bacteria growth

- High tolerance of up to 1.000% overload

- Made in Denmark

- Robust capacitive technology

- Hermetically sealed to IP68

- Electropolished stainless steel 1.4542 (17-4 PH)

- Laser welded with Stainless Steel 1.4541

- ATEX certified (Zone 1, 2, 21, 22)

- High accuracy, High resolution

- Cable length up to 100meters

- Capacity (Emax): 10, 20, 30, 50, 100, 150, 250, 500, 1000kg

- Accuracy: Industrial 0.10%, Precision 0.05%, High Precision 0.025%

- Calibration independent of cable length

- Load cell cable replaceable

- Easy mechanical and electrical installation

- Withstands welding voltages and ESD

- Can be used in both ATEX and non-ATEX installations

Applications:

- Process weighing

- Dynamic weighing

- Tanks and vessels

- Vibration sorters

- Filling and dosing

- Platform scales

- Packaging machines

- Hopper scales

- Belt scales

- Conveyor scales

- Big-bag equipment

- On-board weighing

Click here for examples of Digital Beam Load Cells